Oil Removal

Each oil has properties that characterize it. Each degreasing must therefore take into account the particularity of each of the oils to be removed. Whole, soluble, additive oils require adequate knowledge and methodology to achieve a cleanless that is consistent with the required level.

Each oil has properties that characterize it. Each degreasing must therefore take into account the particularity of each of the oils to be removed. Whole, soluble, additive oils require adequate knowledge and methodology to achieve a cleanless that is consistent with the required level.

It’s obvious that the part to clean cannot be damaged, not even on a microscopic level, so when using a detergent, compatibility with metals & alloys is something to pay attention to. On the other hand when cleaning with solvents, certain plastics may not be compatible.

Read moreA temporary protection against corrosion between production steps could also be required. Inventec has cleaning formulations with a corriosion inhibitor included, avoiding an extra step in your process.

Faced with all these constraints, Inventec has developed several products to provide an adequate solution, suited to your desired process.

Besides the above Inventec can help you with

• Choice of the right process: adaptability,product implementation

• Odour problems, bacterial degradation of baths.

• Difficulties in cleaning mixed oils and certain interactions of pollutants.

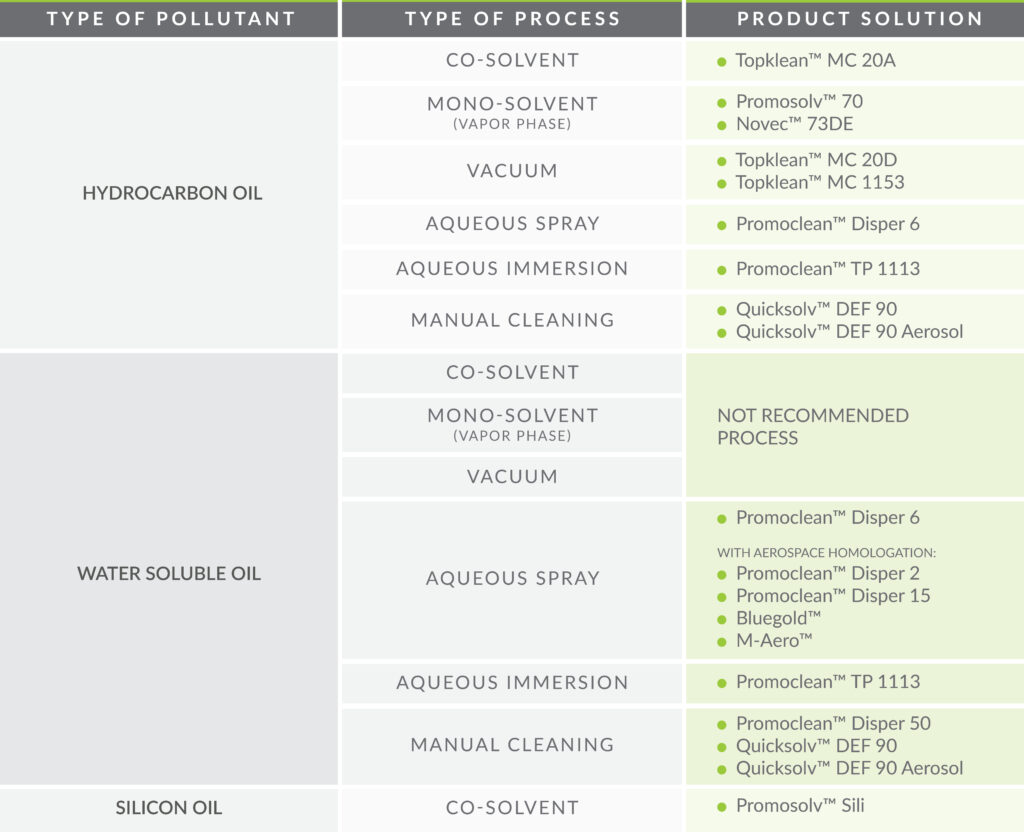

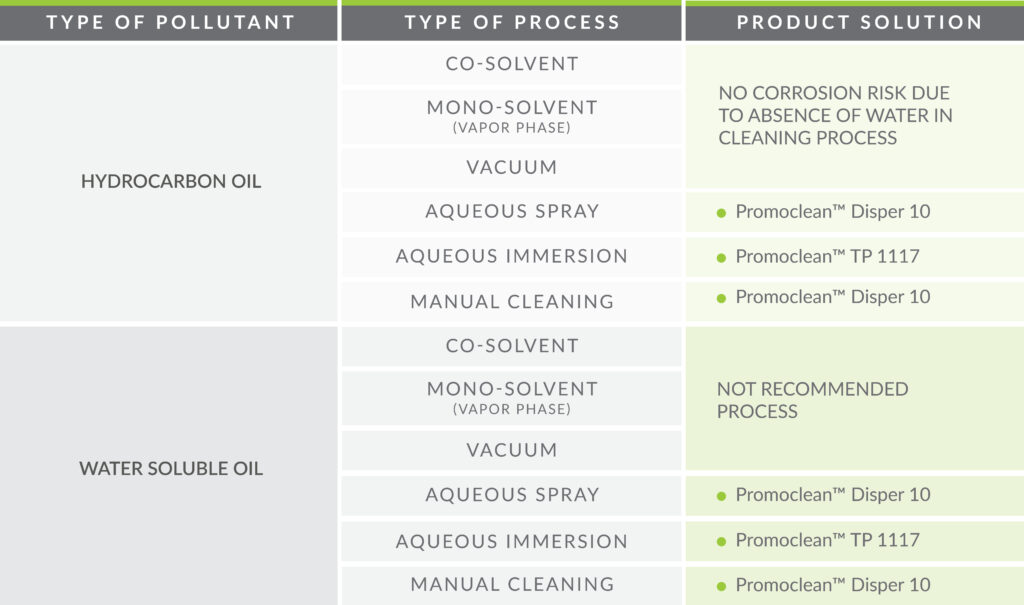

The tables below gives an overview of the different oil types and which product we recommend according to your desired process.

OIL REMOVAL

OIL REMOVAL + TEMPORARY CORROSION PROTECTION

Above table is a non exhaustive list. Inventec offers more products which could be older and for which we have an improved formulation or a fine-tuning to a specific need. You may find a specific product via our search option or contact us for more information.

What are the different processes?

- Co-solvent: solvent process with Topklean products as cleaning agent and Hydrofluoroethers as rinsing solvent

- Mono-solvent: vapor phase cleaning with 1 single solvent for cleaning & rinsing

- Aqueous spray: spray in air / spray in line / immersion jets / water based flushing

- Aqueous Immersion : immersion in tank with options for heating, ultrasonics, agitation (moving of cleaning baskets)

- Manual cleaning: spray, poor or dip in simple tank without heating

Showing all 15 results

-

PROMOCLEAN DISPER 22 ALU

- Removal of grease, heavy oils, burn-in residues & oxides

- Aqueous spray processes

- Compatible with most ferrous & non-ferrous alloys

-

PROMOCLEAN TP 125

- Removal of burnt residues, oxides, polishing pastes, heavy greases & oil

- Aqueous immersion process

- Compatible with ferrous alloys & copper

-

Tailor-made solution

You do not find the perfect product ? We can also offer you some tailor-made solutionContact Us -

QUICKSOLV FIDES

- Oil & dust removal for dielectric cleaning

- For manual spray equipment

- Safe & fast cleaning under power

-

PROMOCLEAN DISPER 13

- Detergent with temporary protection for removing light oils on metallic parts

- Aqueous spray, flush & immersed jets processes

- General cleaner for light contaminations

-

BLUE GOLD

- Degreasing & particle removal from equipment in contact with oxygen

- Aqueous spray & immersion process

- Passes ASTM F-495 and ARP 1775A norm

-

PROMOCLEAN DISPER 11

- Detergent with temporary protection for removing light oils on metallic parts

- Aqueous spray, flush & immersed jets processes

- Compatible with a wide range of metals

-

PROMOCLEAN DISPER 3

- Detergent for removing hydrocarbon oils on metallic parts

- Aqueous spray, flush & immersed jets

- Compatible with a wide range of metals

-

TOPKLEAN MC 1007D

- Heavy contaminants removal

- Mono-solvent, co-solvent or spray process

- Environmental friendly alternative to perchlorethylene & nPB

-

PROMOSOLV SILI

- Silicon oil removal & carrier for silicon deposit

- Vapor phase process

- Excellent cleaning performance & low HSE impact

-

PROMOSOLV 70 T

- Removal of a wide range of contaminants

- Vapor phase process

- Made from recycled solvent

-

3M NOVEC 73DE

- Removal of a wide range of contaminants

- Vapor phase process

- Very low HSE impact & very low surface tension

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 72DE

- Removal of a wide range of contaminants

- Vapor phase process

- High cleaning power & very low GWP

Alternative: PROMOSOLV NEO B1

-

3M NOVEC 71DE

- Removal of a wide range of contaminants

- Vapor phase process

- Medium cleaning power

Alternative: PROMOSOLV NEO B1